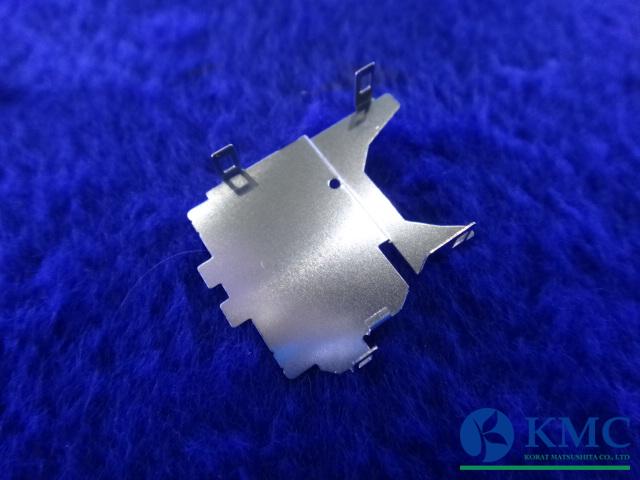

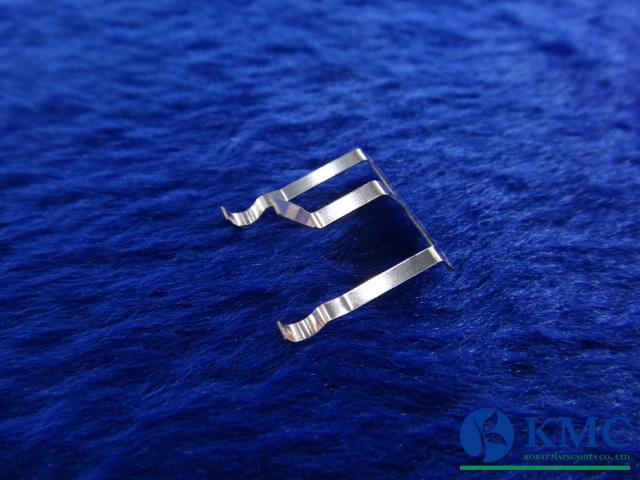

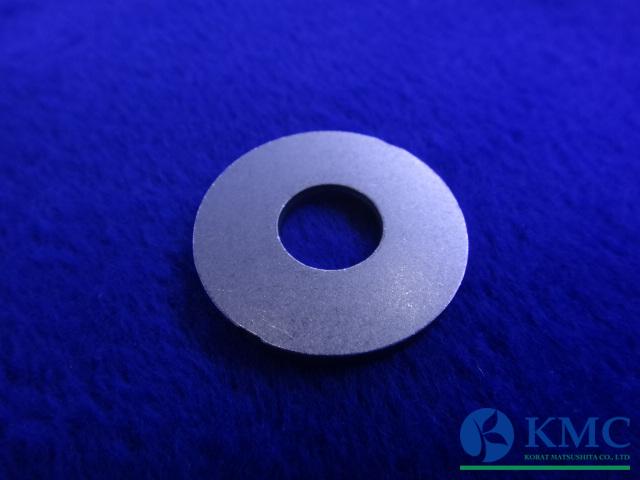

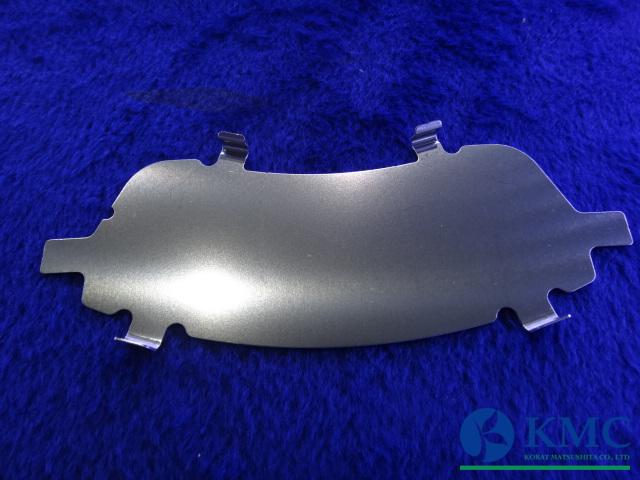

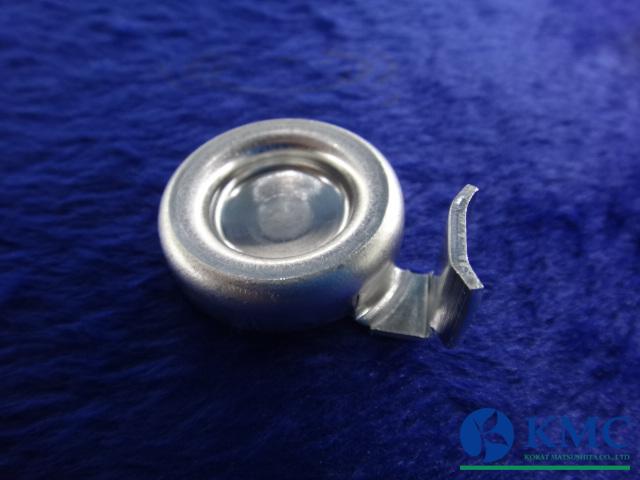

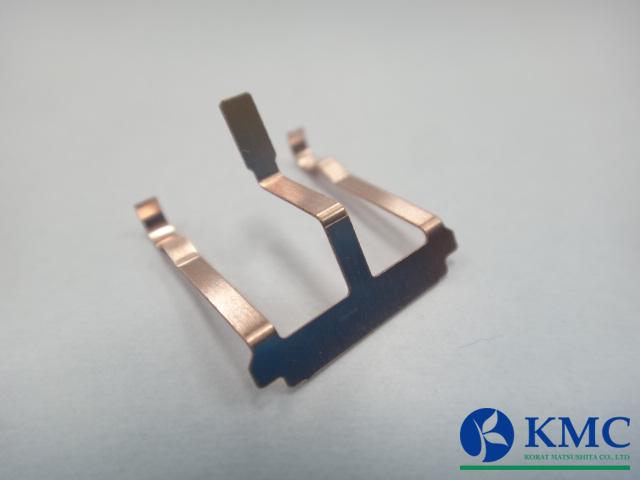

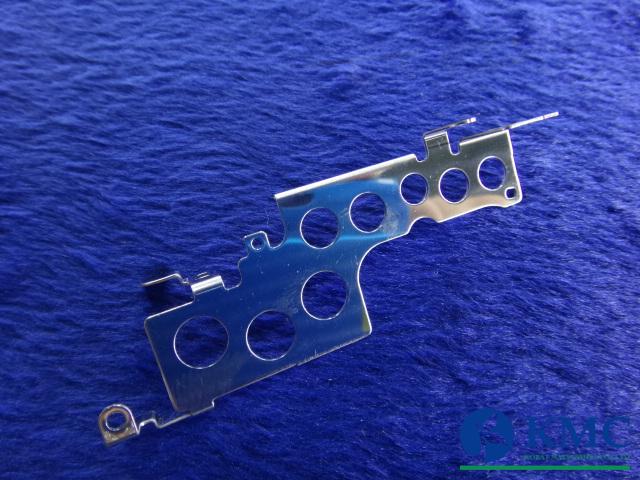

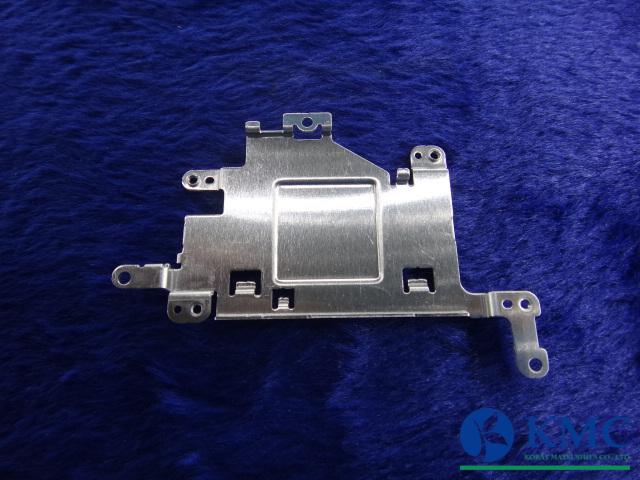

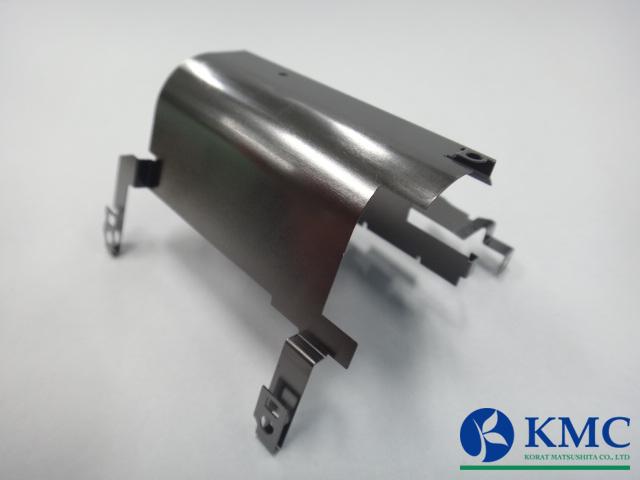

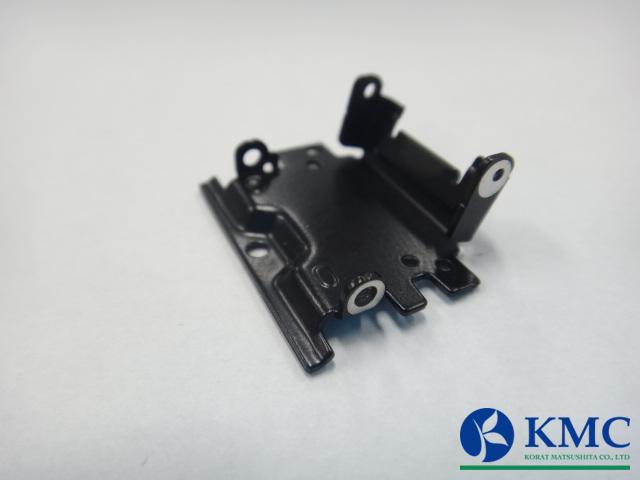

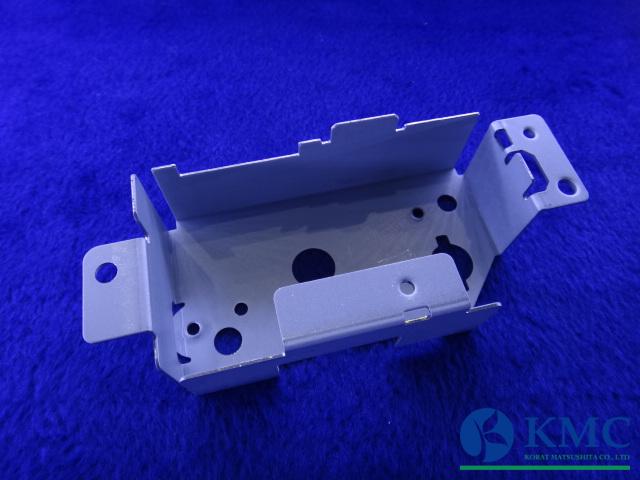

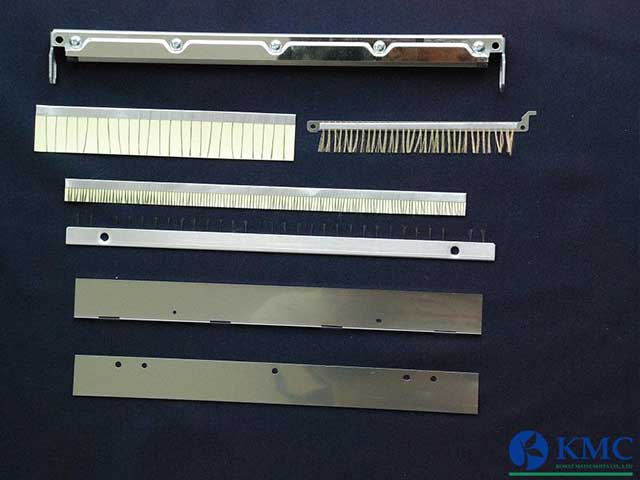

Ever since we commenced our business in Thailand in 1997, we have undertaken several challenges in press operations. Presently, we are capable of handling press processes that require a wide range of thicknesses from 0.05mm to 4mm.

We are able to process a very wide range of different types of materials such as steel plates, stainless steel, aluminum, copper, brass, silver-plated and tin-plated materials, and so forth.

Our processing methods include precision progressive processes, single-stroke processes, transfer processes and other options that we can tailor to meet customers’ needs. We are also well-equipped to provide post-press operations services such as barrel polishing, tapping, welding, plating, caulking, hardening, among others.

We are also able to provide a one-stop mold design and production with our mold department of more than 80 technicians.

We are most capable of handling mass production for our customers using their own molds even though no mold drawings are provided. In this way, we can avoid unnecessary investments in new molds by lowering the cost of transferring the molds that our customers are currently using from various locations such as Japan and China.

Recently, we have been actively introducing servo presses. Currently, there are more than 10 servo presses ranging from 45t to 300t in operation. These have enabled us to improve the quality through highly precise mold operation that require lesser maintenance.

![KMC [EN] KMC [EN]](https://kmcthai.com/en/wp-content/uploads/sites/2/2022/12/kmc-logo.png)